Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Turntable needles are expensive due to the high cost of materials, the complex manufacturing process, research and development costs, the need for compatibility with a wide range of turntable cartridges, and market demand. Investing in a high-quality, compatible turntable needle is worth the cost to ensure excellent sound quality and protection for your records.

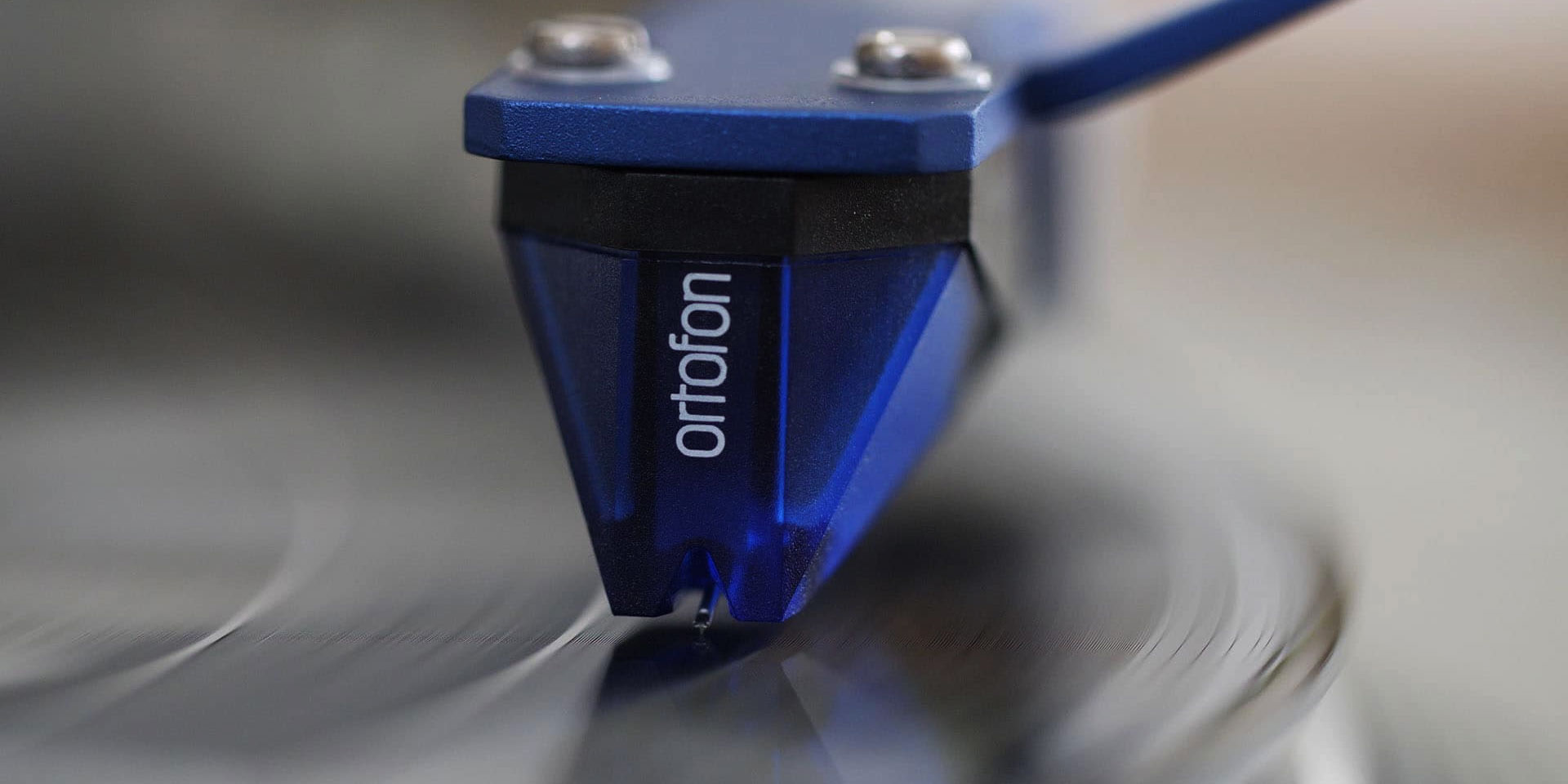

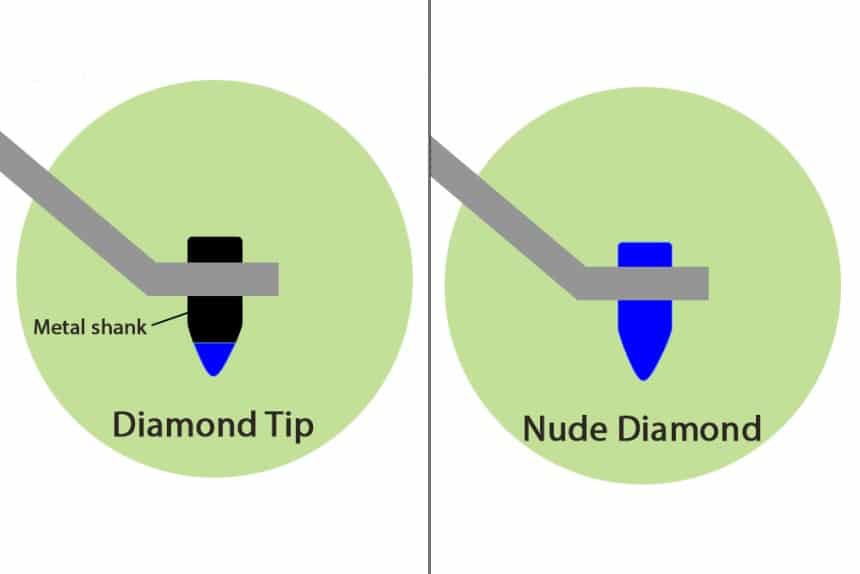

One of the most important factors contributing to the high cost of turntable needles is the quality of the materials used. Turntable needles are typically made of diamond or sapphire, which are both expensive materials. Diamond is the preferred material because it is extremely hard and durable, making it ideal for reproducing high-quality sound. However, diamond is also one of the most expensive materials on the planet. Sapphire, while not as hard as diamond, is still a durable material that can provide excellent sound quality.

In addition to the cost of the raw materials, turntable needles also require precision manufacturing to ensure their quality. A poorly made turntable needle can not only sound bad, but it can also damage your records. The high cost of materials, coupled with the need for precision manufacturing, drives up the price of turntable needles.

The manufacturing process for turntable needles is another factor that contributes to their high cost. Turntable needles are made using a complex process that involves cutting and shaping the diamond or sapphire material. The process requires specialized equipment and skilled labor, both of which add to the cost of the needles.

Additionally, the manufacturing process for turntable needles requires a high level of quality control. Each needle must be carefully inspected to ensure that it meets strict specifications for sound quality and durability. This inspection process is time-consuming and requires skilled technicians, adding to the overall cost of the needles.

Another factor that contributes to the high cost of turntable needles is research and development. The companies that produce turntable needles are constantly working to improve the performance of their products. This research requires a significant investment in time and resources, which is reflected in the cost of the needles.

The research and development process involves testing and refining the design of the needles to ensure that they provide the best possible sound quality. This process may also involve developing new manufacturing techniques or materials that can further improve the performance of the needles. All of these factors add to the cost of the needles.

Turntable needles must be compatible with the turntable cartridges they are designed to work with. There are many different types of turntable cartridges on the market, each with its own set of specifications. This means that turntable needle manufacturers must produce a wide range of needles to meet the needs of different turntable owners.

Producing a range of needles for different cartridges requires a significant investment in time and resources. Each needle must be designed to meet the specifications of a specific cartridge, and the manufacturing process must be adjusted accordingly. This additional complexity adds to the cost of the needles.

Finally, market demand is a factor that contributes to the high cost of turntable needles. As turntables have become more popular, the demand for turntable needles has increased. This increased demand has led to higher prices for the needles.

Additionally, turntable needles are a specialty item, and there are only a few companies that produce them. This lack of competition in the market allows manufacturers to charge higher prices for their products. Turntable needle manufacturers have also faced challenges in sourcing the materials needed to produce their products. Diamond and sapphire, in particular, are scarce resources that can be difficult to obtain in the quantities needed for mass production. This limited supply of materials has further contributed to the high cost of turntable needles.

Yes, turntable needles, also known as cartridges or styluses, make a significant difference in the sound quality produced by a record player. A high-quality turntable needle can bring out the nuances and details of the music in a way that a lower-quality needle cannot. It is essential to use a compatible and well-maintained needle to ensure the best possible sound quality from your turntable.

Many turntable needles do have diamonds, as they are a durable and precise material for the delicate task of reading the grooves of a vinyl record. However, not all turntable needles are made with diamonds. Sapphire and other materials may also be used, although they may not be as durable or accurate as diamond-tipped needles.

Yes, the quality of the turntable needle can have a significant impact on the sound quality produced by a record player. A well-made and well-maintained needle can produce clear, detailed, and accurate sound from a vinyl record. On the other hand, a lower-quality or damaged needle can produce distorted, noisy, or scratchy sound, and even damage the record over time.

The lifespan of a turntable needle can vary depending on how often it is used, how it is maintained, and the quality of the needle itself. Generally, a needle can last anywhere from 500 to 1,000 hours of use. However, if the needle is damaged, worn out, or not properly cared for, it may need to be replaced sooner. Regular maintenance, such as cleaning and alignment, can help extend the lifespan of the needle.

Can I use a cheaper turntable needle on my turntable?

While it may be tempting to save money by purchasing a cheaper turntable needle, it’s important to remember that the quality of the needle can have a significant impact on the sound quality of your turntable. A poorly made or incompatible needle can damage your records or produce subpar sound quality. It’s always best to purchase a high-quality, compatible turntable needle for your turntable.

How often should I replace my turntable needle?

The frequency with which you should replace your turntable needle will depend on how often you use your turntable and the quality of the needle. As a general rule, turntable needles should be replaced every 500 to 1,000 hours of use. However, if you notice a decrease in sound quality or your records are skipping, it may be time to replace your needle.

Can I use a diamond needle on a sapphire cartridge or vice versa?

No, you should never use a diamond needle on a sapphire cartridge or vice versa. Each type of cartridge is designed to work with a specific type of needle, and using the wrong type of needle can cause damage to your records or the cartridge.v

I think you got the answer of ‘Why Are Turntable Needles So Expensive?’ this question. So, turntable needles are expensive for several reasons, including the high cost of materials, the complex manufacturing process, research and development costs, the need for compatibility with a wide range of turntable cartridges, and market demand.

While it may be tempting to purchase a cheaper turntable needle, it’s important to remember that the quality of the needle can have a significant impact on the sound quality of your turntable. Investing in a high-quality, compatible turntable needle is a wise decision that will help ensure that your turntable continues to provide excellent sound quality for years to come.